Singh Tech Computer

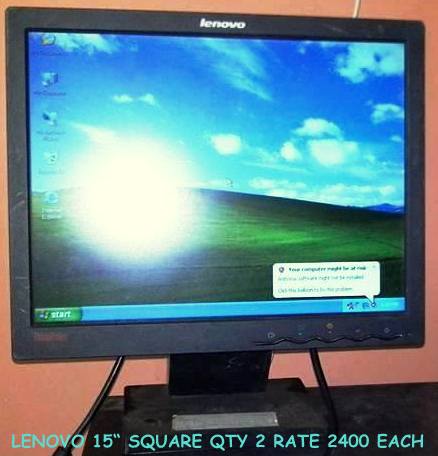

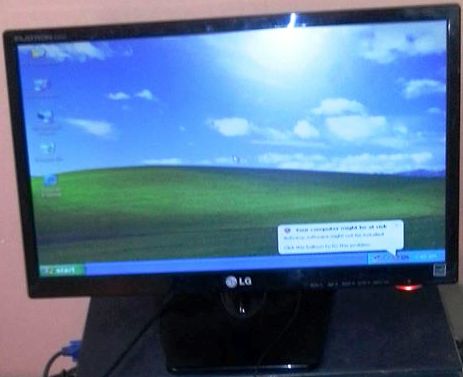

Product

20" LG

Price of the Product

Category of the Product

6

products -

Singh Tech Computer

Our recommended products and services

-

-

A bulk ink system for TIJ (Thermal Inkjet) printers is a solution that allows the use of large quantities of ink instead of traditional cartridges. In this case, the system is designed to use ink tanks, which provides a continuous supply of ink and reduces the need to replace them so frequently. Main components: Ink tank: It is the main container where the ink is stored. In this case, it would have a total capacity of 750ml. Ink supply system: It is the set of tubes and valves that transport the ink from the tank to the print heads. Cartridge: It is a device that connects to the print heads and receives ink from the supply system. Advantages of a bulk ink system: Greater autonomy: Storing a large amount of ink allows printing for longer without the need to change cartridges. Cost reduction: Bulk ink is usually cheaper than cartridges, which can generate long-term savings. Less work interruption: By not having to change cartridges so frequently, the printer's downtime is reduced. Less waste generation: By using larger ink containers, the amount of waste generated by cartridges is reduced. Considerations when choosing a bulk ink system: Compatibility: It is essential to ensure that the bulk ink system is compatible with the TIJ printer and the ink used. Ink quality: The quality of the ink used in the bulk system is crucial for optimal print results. Ease of use: It is important to choose a bulk ink system that is easy to install, use and maintain. Cost: The initial cost of the bulk ink system should be evaluated and compared with the long-term savings it can generate. In summary, a 750ml bulk ink system for TIJ printers is an excellent option for those who print large volumes and want to reduce costs and increase the autonomy of their printers. When choosing a bulk ink system, it is important to consider compatibility, ink quality, ease of use and cost.

-

Hybrid nano-pigment based ink for porous and semi-porous materials requires low energy consumption and the raw materials used are readily available. They are very flexible and the colors are very sharp, intense, luminous, and strong, providing high resistance to abrasion, temperature, oxygen, chemical and environmental elements including water, as well as deterioration caused by exposure to weathering and ultraviolet radiation, thereby increasing their lifespan. They are made from organic materials and eco-friendly dyes free of toxins and for industrial use, which therefore respect the environment by being biodegradable, low-odor, and having a low presence of metallic impurities. Unlike conventional pigments and organic dyes, which other manufacturers use, these contain heavy metals and polluting residues in their composition and can cause unwanted effects such as allergic reactions or carcinogenic processes, the hybrid nano-pigments we use in our inks are free of this type of compound. Key Points: Vivid Colors and Durability: The ink offers vibrant colors and strong resistance to various environmental factors, ensuring long-lasting quality. Eco-Friendly: Made with organic materials and non-toxic dyes, the ink is biodegradable and environmentally responsible. Safety: Free from heavy metals and pollutants, unlike some conventional inks, making it a safer option.

-

The adhesion of inks to the substrate represents one of the major concerns for inkjet printing. Our polymeric ink guarantees the optimal distribution of ink pigments thanks to a technique that combines the reduction of pigments into nanoparticles, together with a method of fixing them to the surface by means of active ionic polymers immersed in the particles of the pigments themselves, which, as time goes by, improve in fixation as they penetrate the substrate. After 24 hours of fixation, the ink improves up to 60% more in fixation than any other type of thermal Inkjet ink. This technology provides better ink flow through the print cartridges, low odor, great formulation stability and greater durability of the ink on the substrate, Demonstrating great resistance to scratching, abrasion and water, maximum drying speed, gloss, color sharpness and light resistance, greater stability during transport and storage of the printed substrate, better effective adhesion of the ink to the substrate, increasing the drying time of the ink (decap) on the print head. These factors help the performance of the ink in the cartridge and with the environment as it is free of many toxic components. The range of polymeric inks has been specially designed to work and respond to industrial production in inkjet equipment using thermal Inkjet heads. They are mainly used for high-resolution digital printing on non-porous materials, such as PE / PP / PET / PVC / OPFD a wide variety of varnishes and coatings, plastics, metals, foils, aluminum and some types of glass.

-