Product

Laser Marker, Fiber Laser Marking System, Laser Marking System and Fiber Laser Marking Machine

Price of the Product

Technical Details

Laser - Fiber Laser,Diode Pump, Nd:YAG Laser

Average /CW Output Power - 20 W

Pulse Repetition Rate - 20-80 KHz

Wavelength - 1062 ± 3 nm

Laser Class - IV

Guide - Laser/Red Aiming Beam - Yes

Ambient Temperature - 25 °C

Power Consumption - < 1 kW

Electrical Connection (Optional) - 230 v / 50Hz - 115 V / 60Hz

Marking area (Optional) - Ø 100 / 150 / 220 mm

Repeatability - 50 Micron

Resolution - 18 Micron

Marking Speed - Up to 10000 mm/sec

Category of the Product

Company website

3

products -

Vision Embesoft Solution

Our recommended products and services

-

-

Desktop system for laser marking safety class 1. PRIMA2 allows marking, stamping and engraving on larger parts of all materials, or on production lines. Standard fonts available: aWaveTM for marking almost all materials, cost-effective laser marking solution IVO4 for marking metals, anodized, painted and some non-transparent plastics Intra for marking transparent plastics O2 for marking organic materials and plastics Green for marking plastics Automator software easy to learn in multiple languages with numerous open parameters to optimize the system based on the material to be used Marking: Management of serial numbers, texts -even archtexts- with full TTF compatibility, Basic geometric figures, shift and date codes in various formats, Barcode management, 2D code marking and datamatrix Import of Dxf - wmf - plt - emf and Raster formats Connections via Ethernet Desktop design with front opening and area inspection window with protective filter Standard 500x550mm loading area - other sizes possible on request Box Command, with start/stop buttons Manual Zeta shaft with 200 mm stroke Do you want a laser bench structure that can be inserted into the production line? Order PRIMA2 with removable side panels or with automatic side doors. Loading area: 500X550 mm

-

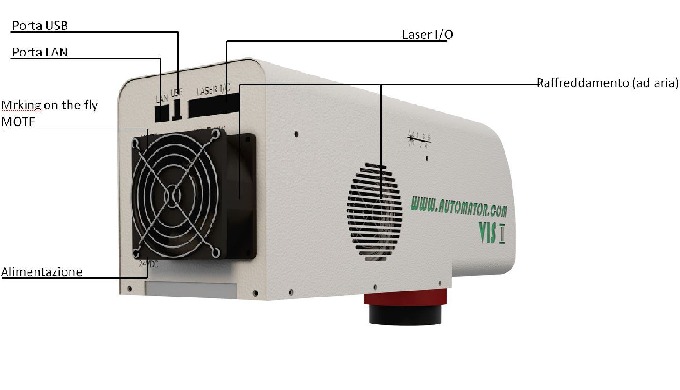

GREENVISII Laser - 5W 10W - Class 4 Second generation Automator laser system in safety class 4, for in-line integrations, in an extremely compact and lightweight unit. Easy to install and use with the new EuGeniusTM marking software. Up to 32 auxiliary axes and infinite combinations for integration with robots or PLCs Pre-diagnostic system with LED indicators The optimized marking head is the result of more than 20 years of experience of Automator in the world of laser marking: a single small body containing source, electronics, galvo system and optics, Easy to integrate, install and, above all, use. Compatible standard sources: green Yag / IVO4 laser Available powers: 5W-10W Standard marking area 110×110 mm (other marking areas available) Mechanical shutter, because safety always comes first Like all second generation Automator lasers (Gen II), the GREENVISII is equipped with a dual-channel mechanical shutter with CE marking, which allows the laser to achieve a SIL3 - PLE safety rating, the highest safety rating for such a device. The dual-contact mechanical safety shutter physically blocks the laser beam when the system signals an event where safety is compromised, or in situations where free access to the dialing area is required in booths. Low-cost lasers do not guarantee this basic requirement and therefore do not comply with current safety regulations.

-

The LW3 Laser Station is aimed at industrial companies that wish to implement laser traceability of parts, components or tools in their production and want to avoid the installation of large enclosures. LW3 is Gravotech's only Class 1 laser for direct marking of large parts. It weighs around 200 kg. The LW3 model brings safety and marking versatility to the operator and the jobsite.

-