Product

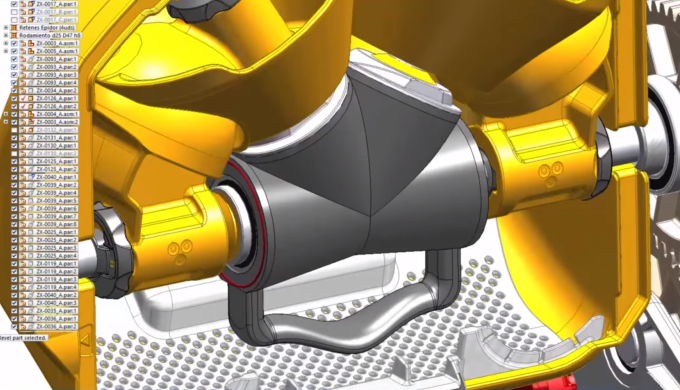

Technologie Synchrone

Le mot synchrone signifie que plusieurs étapes se déroulent simultanément. Cela contraste avec la technologie ordonnée où les étapes se déroulent les unes après les autres.

La technologie synchrone est basée sur l’édition directe et comprend d'autres technologies comme la reconnaissance des fonctions, la reconnaissance des intentions, le pilotage au travers des dimensions.

Le logiciel SolidEdge permet de combiner les technologies synchrones et ordonnées au sein d'une même pièce et des assemblages. Les pièces peuvent être créée à l’aide de la technologie synchrone ou ordonnée ou même avec les deux. De même les assemblages peuvent être constitués de pièces synchrones, de pièces ordonnées et de pièces hybrides (synchrones et ordonnées).

Nous vous recommandons vivement de prendre connaissant de l’ouvrage “ Solid Edge with Synchronous Technology “(ebook de 142 pages) que Matt Lombard a consacré à la technologie synchrone. Matt Lombard est un ingénieur mécanique avec plus de 25 années d’expérience dans le domaine de la CAO mécanique. Il a écrit de nombreux livres dont “ The SolidWorks Bible“. Il écrit : “You know, Siemens really has something with Synchronous Technology. Nothing else in the industry really does what Solidedge can do.”

Nous vous proposons des programmes de formation technologie synchrone en trois jours en nos agences, sur votre site et sous forme de formation en ligne.

Price of the Product

Characteristics of the Product

- Type Logiciel CAO

- Brand Siemens

Category of the Product

Company website

Our recommended products and services

-

-

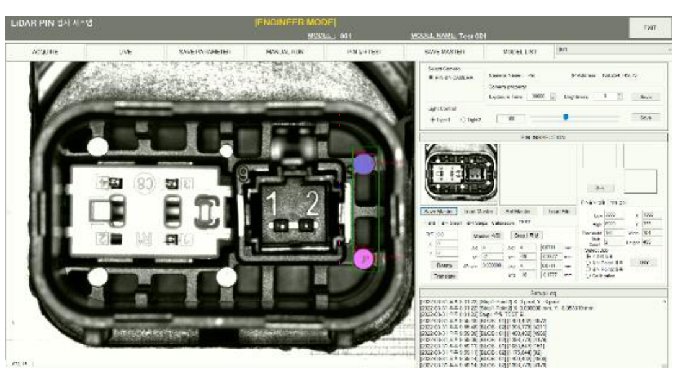

| Machine Vision | : AI Vision Solution It determines the type of defect that cannot be visually confirmed by itself and eliminates human errors so that the case where no defect is found converges to 0. Industrial cameras, special optical devices, sensors, etc. are used to process, analyze, and measure with H/W and S/W to improve product perfection. - Alignment : Automatic determination of defects by finding the location and direction and comparing them with the specified vanity value - Identifier : Locate and identify specified barcodes, characters, labels, colors, shapes, sizes, and unique patterns within a product - Measurement : Determining whether the measured value calculated for the distance between designated positions is within the allowable range - Inspection : Detect defects, blemishes, flaws, and abnormalities throughout the product

-

H/W to utilize existing AI models consists of (1) input (camera, light), (2) control recognition unit (industrial computer or server cloud), and (3) output (monitor, keyboard, and mouse), forming a high-end price range 99% of manufacturers in Korea are small and medium-sized enterprises, and economic conditions prevent them from adopting AI models The "Hyper Q Edge Camera" is connected to the camera with a neural network chip (NPU) and can upload and use AI models on its own, without the need for a separate server or industrial computer There is no need for data transfer in the cloud, and AI computation is processed on its own in the device, with the advantages of privacy protection and low cost. It has versatility that can be selected and used according to the uploaded AI model, and can be used in various industrial sites or requirements -feature : Built-in neural network chip (NPU) Camera (resolution) can be changed according to customer requirements Equipped with customized AI models -merit : Low-cost H/W configuration Don't use the cloud to protect your privacy Versatility used in various industrial sites Various AI models can be installed according to the purpose

-

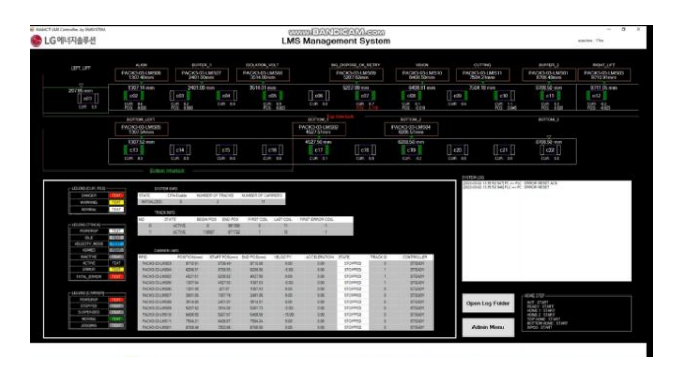

| LMS_Linear Motion Systems | : Smart Factory Solution It is a control solution for efficient management and productivity improvement of LMS (Linear Motion Systems), a next-generation logistics transport system. [ Features ] 01. Clean room, can be driven inside vacuum chamber 02. Capable of operating in inert gas, high temperature, and chemicals 03. Transport without cable bears, advantageous for clean room processes 04. Improved process times with individual carrier control 05. Carrier circulation structure increases facility production - Realization of precise precision through RFID matching for each carrier - Calculation of optimal logistics transport routes through prediction of future conditions - State preservation through real-time visualization - Removal of bottlenecks such as communication speed improvement

-