Product

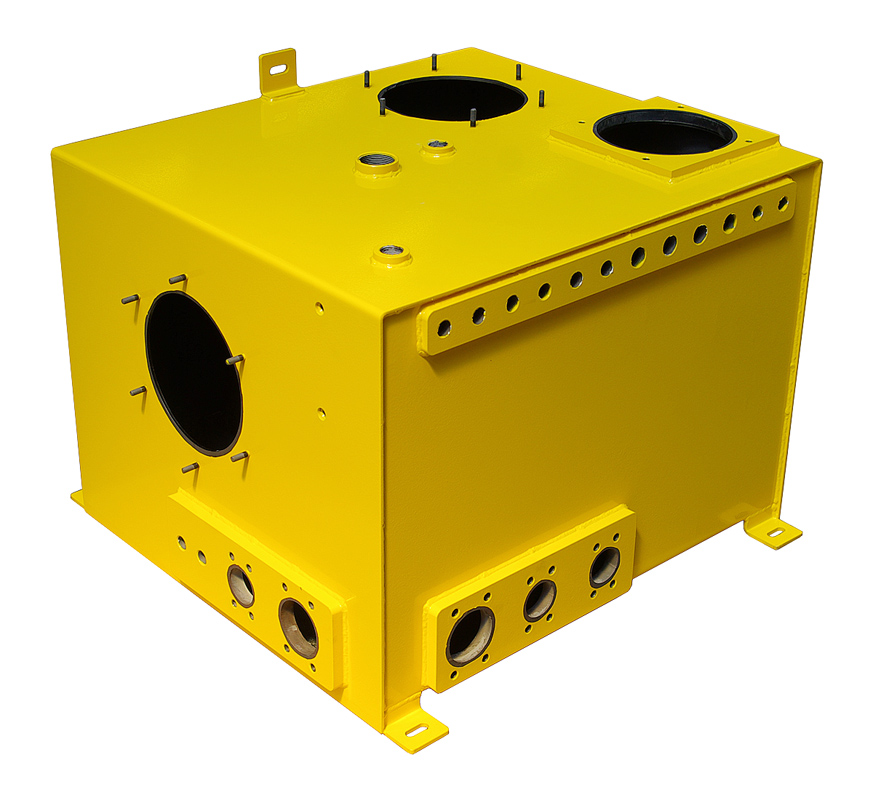

Scraper and waste container.

The tipping container serves primarily for storing chips from machine tools. For this purpose, the container is equipped with a double bottom with a sieve and a drain cock. The container can be transported manually by means of suspension lugs on a castor, fork lift truck or crane. When using a forklift truck, the tilting operation is performed automatically when the locking lever fitted with a transport lock is released.

The tipping chipping container is generally also suitable for storing another type of waste up to the maximum load capacity of the container.

Our chip and waste dumpster will help you to optimize your chip management.

For more information on the tipping container, visit www.dendera.cz

Price of the Product

Category of the Product

Company website

Our recommended products and services

-

-

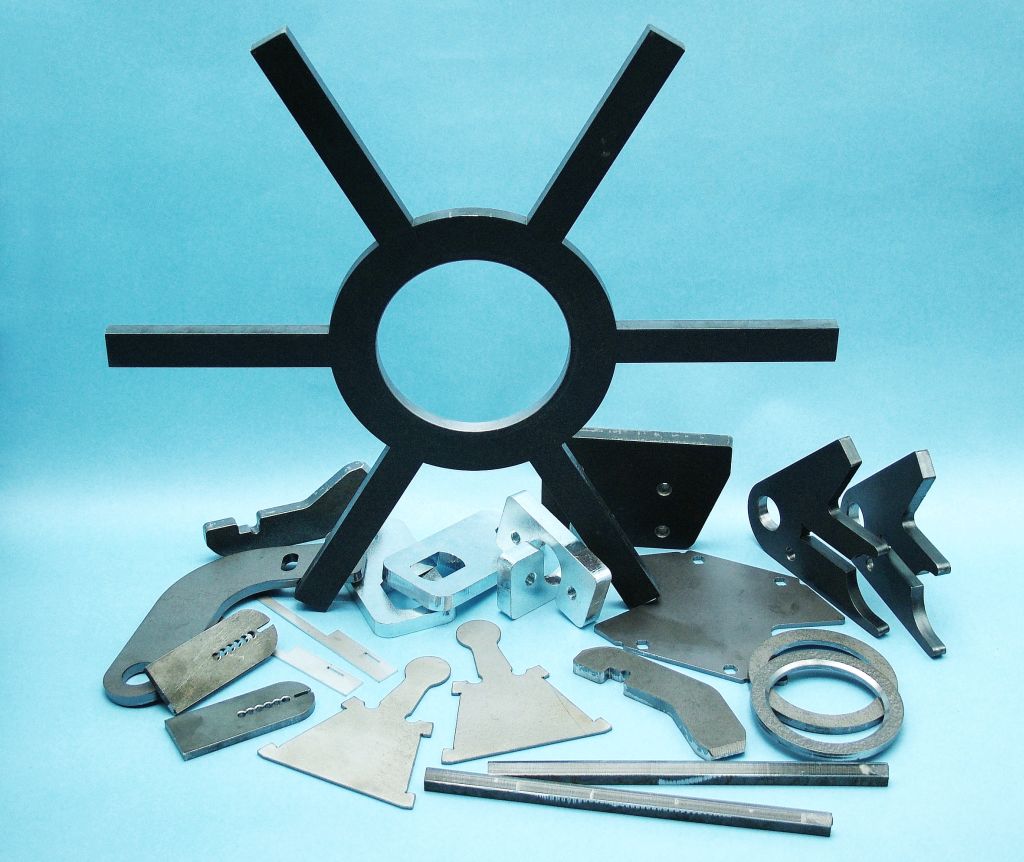

PUNCHING MACHINE AND EDGING MACHINE At Pinholt Metal Working we can also offer: Cut on machine scissors Revolver Press Eccentric Press Hydraulic Bending Machine Assembly tasks are also carried out according to the customer's instructions.

-

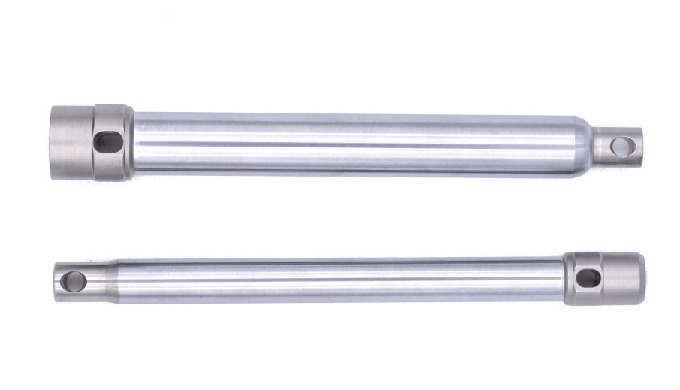

The piston pin is a stainless steel industrial tool. It is often used for paint pumps or paste applications. The part is subject to heavy wear: sealing area with hard chrome plating + grinding. Product description : Sector : Industrial tools Function : Paint pump, application of pasty products Material: Stainless steel

-

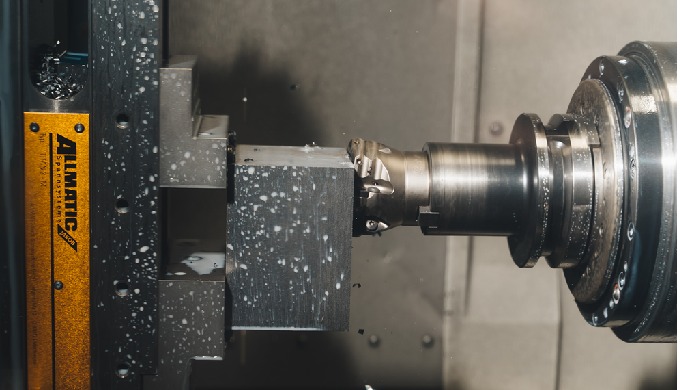

At IRADI we specialize in manufacturing according to drawing, from prototypes and unit batches to short and medium series requiring machining on lathes, milling machines, and machining centres. We work with a wide range of materials: including bronze, aluminium, stainless steel, other alloys, and all types of technical plastics. We also provide assembly and sub-assembly mounting to our customers. Because of our close proximity to our customers, we have a wealth of knowledge that enables us to provide them with comprehensive machining solutions, from material procurement to final product finishing. Ingenieria Iradi manages the contracting of all the services required by the product, such as: thermal, coating and surface treatments, welding, shipment management, special packaging, etc. A comprehensive tailor-made service for each project. To achieve maximum precision in the parts we manufacture we have a 3D CNC measuring machine, with a measuring field of 700 x 700 x 500, which is subject to a strict calibration plan and is isolated in a room with environmental control, both temperature and humidity, to ensure traceability.

-